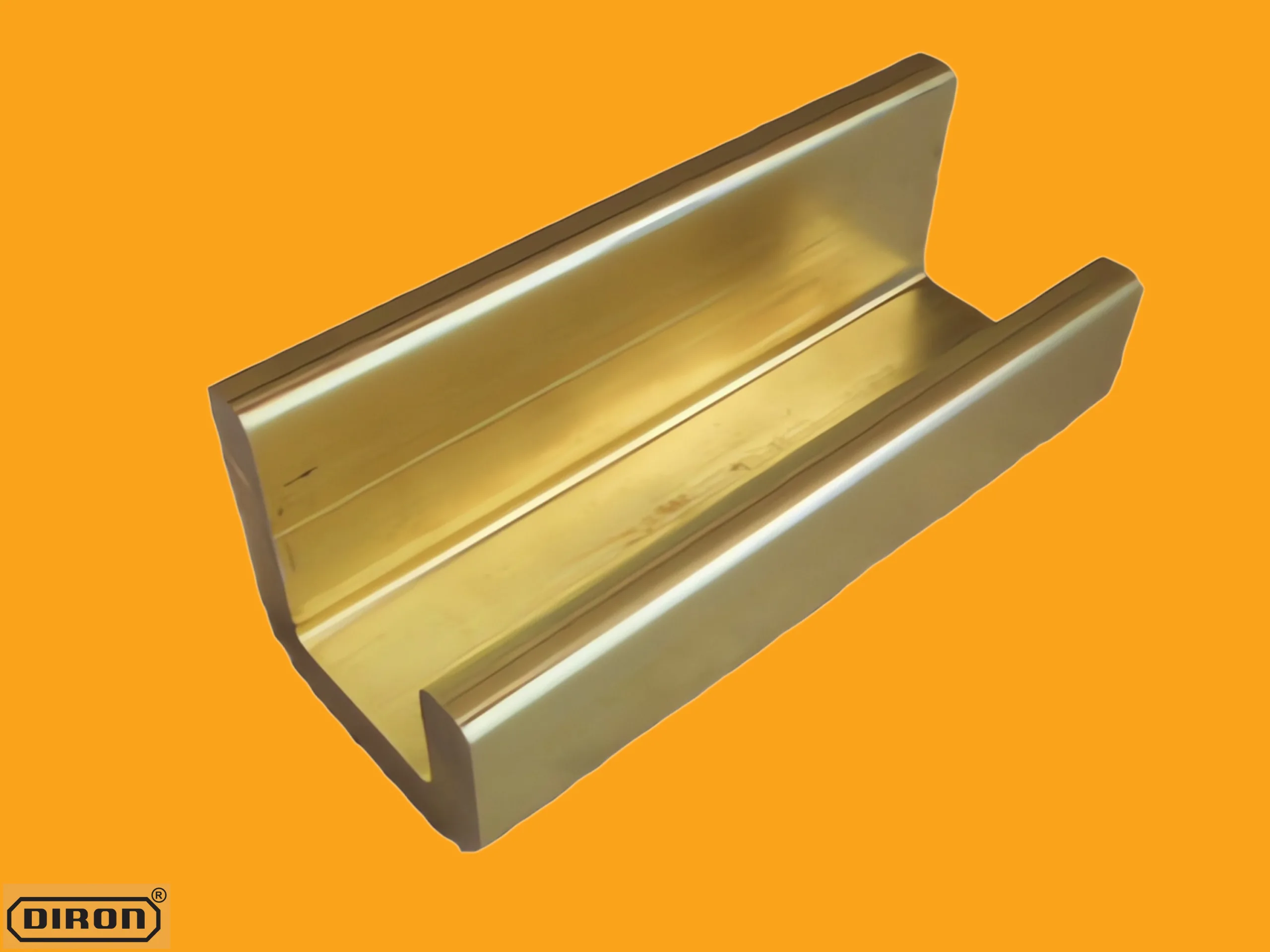

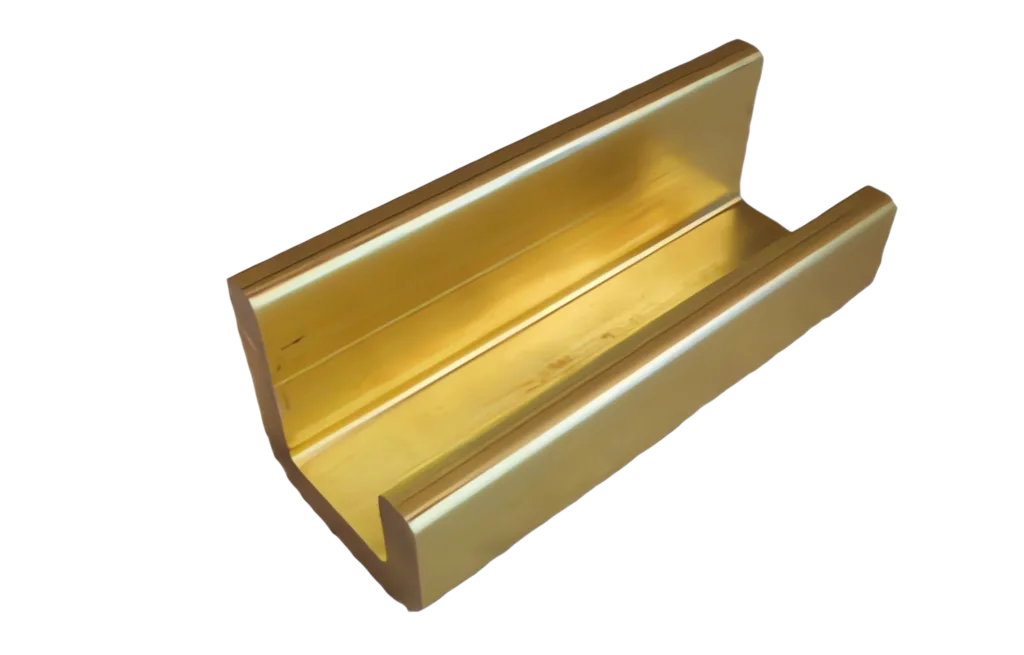

Part Name: Bronze Strip Wear 5T8365

Part Number: 5T8365

Basic Info.

| Part no. | Bronze Strip Wear 5T8365 | Material | Iron |

| Type | Bronze Strip Wear | Weight | 1.37kg |

| Model | 14G, 14H, 14H NA | Transport Package | Wooden Box |

| Trademark | DIRON | Origin | Luoyang City |

| HS Code | 84099991 | Production Capacity | 5000PCS/Year |

Product Details

- Item Model:Bronze Strip Wear 5T8365

- Date First Listed:2024年11月29日

- Manufacturer:Diron Parts

Product Description

- Part Number:Bronze Strip Wear 5T8365

- Part Type:Bronze Strip Wear

- Compatible Equipment:Motor Grader for Caterpillar

Bronze Strip Wear in Motor Graders plays a specialized role in providing protection, enhancing durability, and improving the precision of blade movement. Unlike standard wear strips made from steel or carbide, bronze wear strips are known for their self-lubricating properties, excellent wear resistance, and low friction characteristics. They are typically used in areas where smooth sliding or reduced wear between moving parts is critical.

Functions of Bronze Strip Wear in Motor Graders:

1. Reducing Friction and Wear:

- Bronze is a low-friction material that minimizes wear between the grader blade and adjacent components. This property ensures smooth movement and operation, reducing energy loss due to friction.

- The self-lubricating nature of bronze helps to decrease the need for frequent lubrication, making operations more efficient and maintenance easier.

2. Protecting High-Contact Surfaces:

- Bronze Strip Wear acts as a sacrificial layer, absorbing wear and protecting critical surfaces like the blade support or moldboard guides from damage.

- By reducing direct metal-to-metal contact, it extends the life of both the blade and the grader's structural components.

3. Enhancing Blade Movement Precision:

- The low-friction characteristics of bronze allow the blade to move with greater precision and smoothness. This is particularly important for grading tasks that require fine adjustments and accurate leveling.

- It ensures consistent and even blade positioning, which is crucial for achieving high-quality surface finishes.

4. Corrosion Resistance:

- Bronze has excellent resistance to corrosion, making it ideal for use in environments where moisture, dirt, or corrosive elements like salt (e.g., in snow removal) are present.

- This corrosion resistance ensures the strip remains effective for longer periods, even in harsh working conditions.

5. Minimizing Vibration and Noise:

- Bronze’s damping properties help absorb vibrations and reduce operational noise, enhancing operator comfort and protecting the machine from excessive vibration-related wear.

Advantages of Using Bronze Strip Wear:

- Self-Lubricating: Reduces the need for frequent lubrication, minimizing maintenance efforts.

- Low Friction: Ensures smooth and precise blade movement, enhancing grading accuracy.

- Durability: Resists wear, impact, and corrosion, providing long-lasting protection.

- Vibration Damping: Reduces vibrations, improving the grader’s operational stability and comfort.

Applications of Bronze Strip Wear in Motor Graders:

- Moldboard Slide Rails: Used to reduce wear and friction between the moldboard and support structures.

- Blade Guides: Ensures smooth and precise blade movement during grading operations.

- Pivot Points or Bearings: Provides a low-friction interface at pivot points to enhance movement and reduce wear.

Conclusion:

In Motor Graders, Bronze Strip Wear is essential for ensuring smooth, precise, and efficient blade movement while providing superior protection to critical components. Its low friction, self-lubricating properties, and corrosion resistance make it an ideal choice for enhancing durability and reducing maintenance, particularly in demanding or high-precision grading tasks.

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: FOB

Q4. How about your delivery time?

A: Generally, it will take 20 to 30 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from

Advatange One

Diron Parts Group Have Its Own Factory Ensure That We Offer Better Price For Customers. Besides, Diron Corporate With Some Reliable Principal Manufacturers, So Diron Also Supply Customer Other Quality Spare Parts.

Advatange Two

With 18 Years Experience In Manufacturing And Exporting, Diron Has A Team Of Knowledgeable Engineers, Inspectors, And Skilled Workers

Advatange Three

The Products Export To More Than 80 Countries In America, Europe, Africa, The Middle East And So On. Reliable Quality Parts Won Trust From Valued Customers.