Technical News

Components of the Excavator Track System

The track system of an excavator is made up of several key components. Below is a detailed list of the parts that make up the excavator's track system, including the ones you mentioned, along with Wikipedia links for further reference:

- Track Shoe Assembly:

The track shoe assembly consists of multiple track shoes, which are the components that come into direct contact with the ground and provide traction. The assembly includes the track shoes, connecting pins, and links. Track shoe assemblies are typically designed based on ground conditions and work requirements. - Track Chain:

The track chain is made up of multiple track links, which are connected by pins and shafts. It transmits the power from the drive mechanism and ensures the smooth operation of the track system. - Tips:

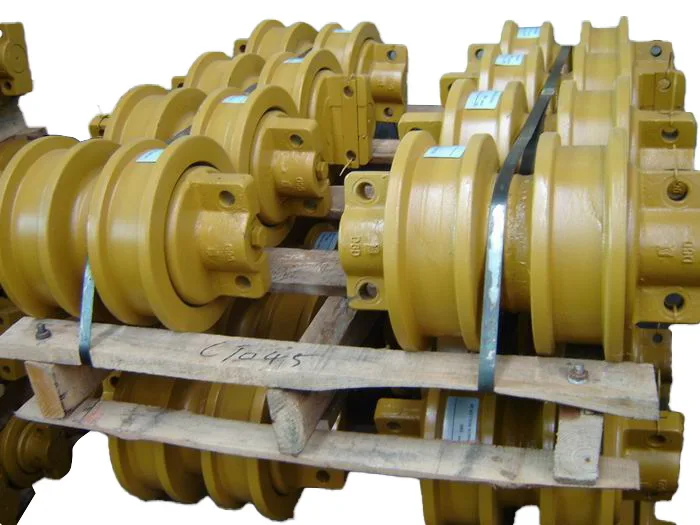

Track tips, though generally associated with the bucket in digging and breaking applications, are sometimes involved in the design of the track system to reinforce parts of the track that come into contact with soil, particularly in heavy machinery. - Rollers:

Rollers are located on both sides of the track chain to support it and help it move smoothly. They reduce friction between the track and the ground, extending the life of the track system. - Segment:

The track segment consists of smaller sections, each comprising track shoes and connecting pins. The design of the track segment determines the track’s load-bearing capacity and its ability to adapt to different working conditions. - Idler:

The idler is located at the front end of the track system and is used to adjust the tension of the track chain. It helps maintain stability and ensures smooth operation of the track system. - Hub:

The hub connects critical components like the drive sprocket and rollers, helping to distribute pressure and ensure the track chain operates smoothly. It is an essential part of transmitting power and supporting the track system. - End Bits:

End bits are located at the ends of the track, reinforcing and protecting the connection parts of the track system. Made from wear-resistant metal, they help resist friction and impact, extending the life of the track system. - Drive Sprocket:

The drive sprocket is located at the rear of the track system and engages with the track chain's gears. It transmits the power from the engine to the track, enabling forward and backward movement. - Tensioner:

The tensioner helps adjust the tension of the track, ensuring the track chain remains at the proper tightness during operation, preventing it from becoming too loose or too tight. - Track Support:

Track support is found inside the track system and helps support the track chain and rollers, ensuring the stability of the entire track system.

These components work together to ensure the stability, durability, and adaptability of the track system, allowing the excavator to operate efficiently on various terrains and under different working conditions.