Technical News

Diesel Engine Cylinder Head Torque Specifications

Diesel Engine Cylinder Head Torque Specifications

The torque specifications for a diesel engine cylinder head are crucial to the engine's performance and longevity. Incorrect torque settings for the cylinder head bolts can lead to cylinder head deformation, seal failure, and even severe engine damage. This article provides an overview of diesel engine cylinder head torque specifications, standard tightening steps, and essential precautions to ensure safe and effective installation.

1. Overview of Diesel Engine Cylinder Head Torque Specifications

Torque specifications for diesel engine cylinder head bolts are not universally fixed; they vary depending on the engine model and manufacturer. Generally, the torque range for most diesel engines is between 50 and 200 Newton-meters (Nm). The following steps outline common torque values for diesel engines, typically applicable to medium and small-sized engines. However, specific torque values should always be verified using the engine’s service manual.

2. Standard Torque Steps for Diesel Engine Cylinder Head Bolts

Initial Tightening Phase

In this phase, all cylinder head bolts are initially tightened to a moderate torque, generally within the 30-50 Nm range. This initial tightening helps ensure that the cylinder head is evenly seated and prepared for subsequent stages.

Intermediate Phase

Following a specified sequence, the bolts are further tightened, typically to 80-120 Nm. This stage helps the bolts gradually handle increased loads, minimizing stress differences on the cylinder head surface.

Final Tightening Phase

The bolts are brought to the recommended final torque value, which is often 150-200 Nm, depending on manufacturer specifications. This phase ensures that the bolts reach the final tension required to secure a reliable seal.

3. Tightening Sequence and Torque Angle Method for Diesel Engine Cylinder Heads

Tightening Sequence

It is standard practice to tighten the cylinder head bolts from the center outward, following a diagonal or crosswise pattern. This pattern allows even distribution of pressure across the cylinder head, reducing the risk of deformation or seal failure due to uneven tightening.

Torque Angle Method

Some diesel engines use the “torque angle method” in the final phase. In this approach, bolts are initially tightened to a specified torque, followed by an additional turn by a specified angle (such as 90° or 120°). This method ensures more precise pressure distribution across the diesel engine cylinder head.

4. Key Precautions for Diesel Engine Cylinder Head Torque

- Reference the Service Manual

Torque specifications for each diesel engine cylinder head can vary, so always refer to the manufacturer's service manual for the specific engine model to ensure accuracy and safety. - Bolt Lubrication

Certain cylinder head bolts require lubrication before installation. Lubrication reduces friction, leading to more accurate torque application and reduced deviation. - Avoid Over-tightening

Excessive torque can cause damage to the cylinder head and bolts, leading to seal failure and possible engine damage. Using the correct torque wrench and following each step carefully is essential for preventing these issues.

Conclusion

The torque specifications for a diesel engine cylinder head are precise measurements that directly affect the engine's seal and longevity. Proper initial, intermediate, and final torque settings, along with an appropriate tightening sequence and method, can greatly enhance the reliability and lifespan of a diesel engine. By following these guidelines and using the correct tools, you can ensure that the diesel engine cylinder head is installed securely and effectively.

Click here to download the engine manual

Diron Parts: Your Trusted Source for Diesel Engine Cylinder Head and Replacement Parts

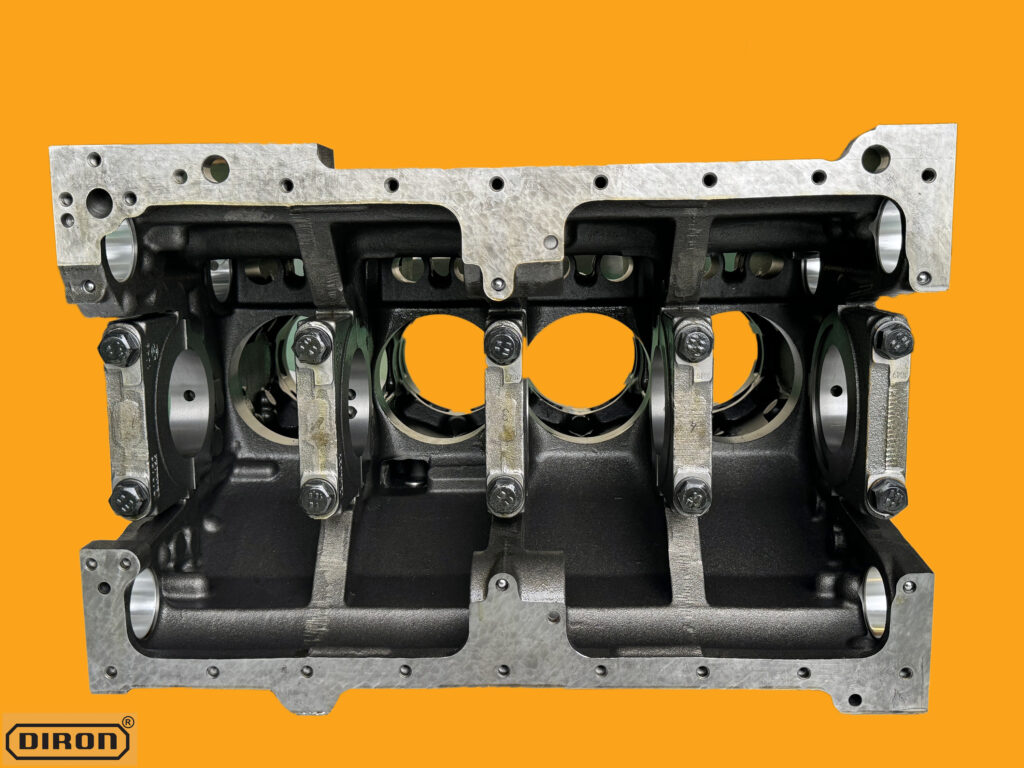

Diron Parts is a top-tier supplier dedicated to providing high-quality parts for diesel engines, specializing in diesel engine cylinder heads, cylinder blocks, and replacement Caterpillar parts. Whether you’re looking to exchange a worn cylinder head or need reliable components for a cylinder block rebuild, Diron Parts has a comprehensive selection that caters to a wide range of heavy-duty diesel engines.

One of Diron Parts’ key strengths lies in its extensive inventory, designed to meet the needs of industries that rely on durable and dependable diesel engines. Their commitment to quality is evident in the replacement Caterpillar parts they offer, which are engineered to meet or exceed OEM standards. From cylinder head exchange services to complete cylinder block replacements, each part is manufactured with precision to ensure optimal engine performance and longevity.

For more information on their full product line and to browse parts, visit the Diron Parts website at dironpartsgroup.com. With a focus on performance and reliability, Diron Parts is a trusted partner for keeping your engines running smoothly.