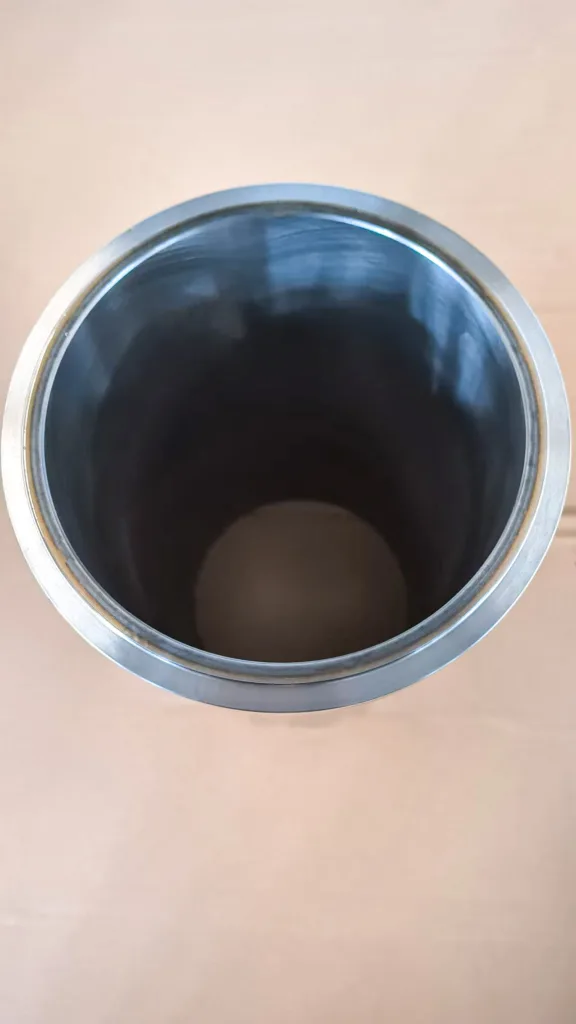

Part Name: Cylinder Liner 2P8889 1105800

Part Number: 2P8889 1105800

Basic Info.

| Part no. | Cylinder Liner 2P8889 1105800 | Material | Iron |

|---|---|---|---|

| Type | Cylinder Liner | Weight | |

| Engine No. | 3304, 3306 | Transport Package | Wooden Box |

| Trademark | DIRON | Origin | Luoyang City |

| HS Code | 84099991 | Production Capacity | 5000PCS/Year |

Product Details

- Item Model:2P8889 1105800

- Date First Listed:2024年11月15日

- Manufacturer:Diron Parts

Product Description

- Part Number:Cylinder Liner 2P8889 1105800

- Part Type:Cylinder Liner

- Compatible Equipment:3304, 3306 Diesel Engine suit for Caterpillar Equipment 3715941

In a diesel engine, the liner (cylinder liner) is a critical component of the cylinder assembly, serving the following important functions:

1. Forms the Working Surface

- The cylinder liner provides the precise sliding channel needed for the piston’s reciprocating motion.

- It must have high strength and wear resistance to withstand high temperatures, high pressure, and friction with the piston rings.

2. Sealing Function

- Together with the piston rings, the liner helps form a sealed combustion chamber, preventing gas leakage and ensuring combustion efficiency.

- Its sealing capability directly affects the engine's compression ratio and power output.

3. Heat Transfer

- The liner transfers the heat generated during combustion to the cooling system (e.g., water cooling or air cooling), preventing the engine from overheating.

- It requires excellent thermal conductivity to maintain a stable working temperature.

4. Reduces Wear

- The liner protects the engine block, reducing wear caused by direct contact between the piston and the cylinder block.

- When the liner is severely worn, it can be replaced without the need to replace the entire engine block, thereby lowering maintenance costs.

5. Corrosion Resistance

- The inner wall of the liner must resist corrosion from combustion gases, while the outer wall must resist corrosion from the cooling fluid. Therefore, materials are often made of special alloys or treated with surface coatings.

6. Supports Assembly Flexibility

- In some diesel engines, wet or dry cylinder liner designs are used for easy maintenance and replacement:

- Wet cylinder liners: Directly contact the coolant, providing better heat dissipation.

- Dry cylinder liners: Do not contact the coolant directly, resulting in a more compact structure.

The cylinder liner is essential for the reliable operation of a diesel engine over time, and its design and manufacturing quality directly impact the engine’s performance and lifespan.

Purchase Notice

Diron Parts is a diesel engine parts manufacturer and wholesaler from China. Mainly engaged in: diesel engine cylinder heads, cylinder blocks, oil seals, etc. We provide aftermarket parts for Caterpillar, Komatsu, Cummins and other brand diesel engines. Our products can not only perfectly match the above brands, but also have the highest product quality and the most favorable wholesale price. If you are interested in our products, please contact us.