Technical News

General Guidelines for Tightening Cylinder Head Bolts

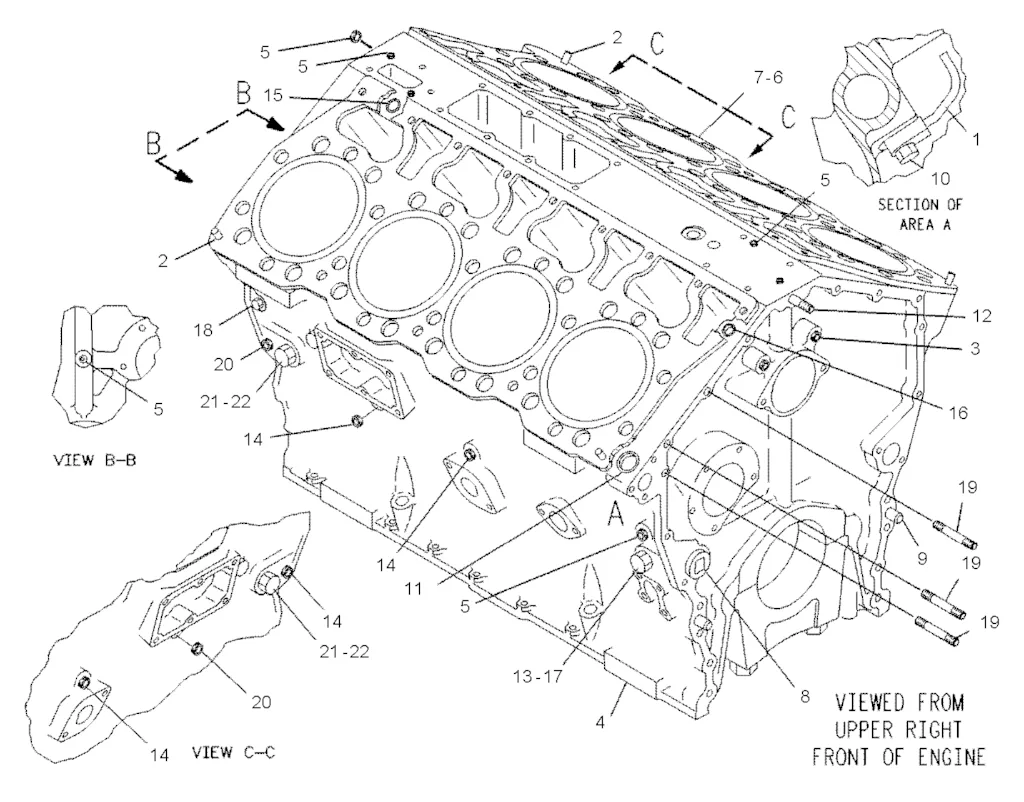

The cylinder head bolt tightening sequence and torque specifications for a diesel engine depend on the engine's make and model. Below is a general guideline used in most diesel engines, but you should always consult the manufacturer’s service manual for accurate details.

General Guidelines for Tightening Cylinder Head Bolts

Tightening Sequence:

- The tightening sequence typically follows a spiral pattern, starting from the center bolts and moving outward. This ensures even distribution of clamping force on the head gasket.

- The bolt positions are usually numbered in the following manner:

10 6 2 4 8 9 5 1 3 7

Steps for Tightening:

- Clean the bolt threads and apply engine oil or the specified lubricant, as recommended in the service manual.

- Tighten bolts in three stages:

- Stage 1: Tighten all bolts to an initial torque (e.g., 30–50 Nm).

- Stage 2: Tighten all bolts to a medium torque (e.g., 70–100 Nm).

- Stage 3: Tighten all bolts to the final torque or angle specification, often using a torque-to-yield (TTY) method.

Torque Specifications (Example for a Diesel Engine):

- Stage 1: 40 Nm (29 ft-lbs)

- Stage 2: 80 Nm (59 ft-lbs)

- Stage 3: Tighten further by 90–120° angle rotation (always check the service manual).

Important Notes:

- Bolts Replacement: Many diesel engines use torque-to-yield (TTY) bolts, which stretch slightly during installation and must be replaced after each use.

- Surface Preparation: Ensure the cylinder head, block surface, and bolts are clean and dry. Residual oil or debris can affect the clamping force.

- Sequence Adherence: Following the exact tightening sequence and torque specifications ensures even clamping pressure and prevents head warping.

- Special Tools: Some engines require the use of specialized torque-angle gauges for TTY bolts.