Technical News

Cylinder Head: 8 Questions to Understand this Engine Essential

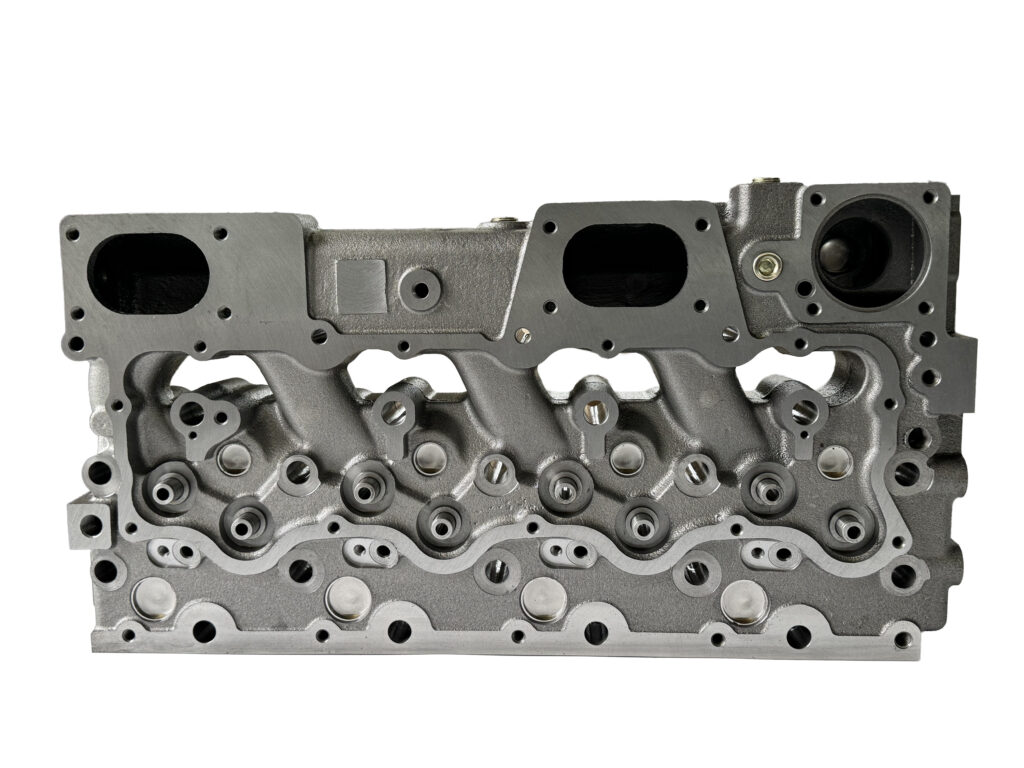

The cylinder head is a critical, yet often unseen, component in your car's engine. It's bolted on top of the engine block, sealing the cylinders and playing a vital role in the combustion process. But what exactly is a cylinder head, and why is it so important? Let's explore 8 key questions to decode the mysteries of the cylinder head.

1. What is a Cylinder Head and What Does it Do?

Imagine the engine block as the body of your car's engine, and the cylinder head as its "head," sitting right on top. The cylinder head is a complex component that closes the top of the engine cylinders, creating the combustion chamber where the magic of power generation happens. But it's not just a lid! The cylinder head is also a busy hub, housing many crucial parts that control the engine's breathing and combustion processes.

Key Functions of a Cylinder Head:

- Seals the Combustion Chamber: It forms a tight seal at the top of the cylinder, essential for compressing the air-fuel mixture and containing the explosion during combustion.

- Houses Valves: It provides mounting points and guides for intake and exhaust valves, which control the flow of air and fuel into the cylinder and exhaust gases out.

- Supports the Camshaft (in some designs): In Overhead Cam (OHC) engines, the cylinder head also houses the camshaft(s) that operate the valves.

- Contains Intake and Exhaust Ports: Passageways within the cylinder head allow the air-fuel mixture to enter and exhaust gases to exit the combustion chamber efficiently.

- Provides Spark Plug or Injector Location: It provides a location for spark plugs (in gasoline engines) or fuel injectors (in diesel engines) to initiate or deliver fuel for combustion.

- Facilitates Engine Cooling: Cylinder heads contain coolant passages that are part of the engine's cooling system, helping to dissipate the intense heat generated during combustion.

2. What are the Different Types of Cylinder Heads?

Cylinder heads are not one-size-fits-all. They are designed in various configurations to suit different engine designs and performance requirements. Here are some key classifications:

Based on Valve Arrangement:

- Flathead/L-Head: Valves are located beside the cylinder, in the engine block itself, not in the head. Older design, less efficient.

- Overhead Valve (OHV) or Pushrod: Valves are in the cylinder head, operated by pushrods and rocker arms from a camshaft in the engine block. Simpler design, often used in V-engines.

- Overhead Camshaft (OHC): Camshaft(s) are located in the cylinder head, directly or via short rockers operating the valves. More complex, allows for better high-speed performance and valve control.

- Single Overhead Camshaft (SOHC): One camshaft per cylinder head, typically operating both intake and exhaust valves.

- Double Overhead Camshaft (DOHC): Two camshafts per cylinder head, one for intake valves and one for exhaust valves, allowing for even greater valve control and performance.

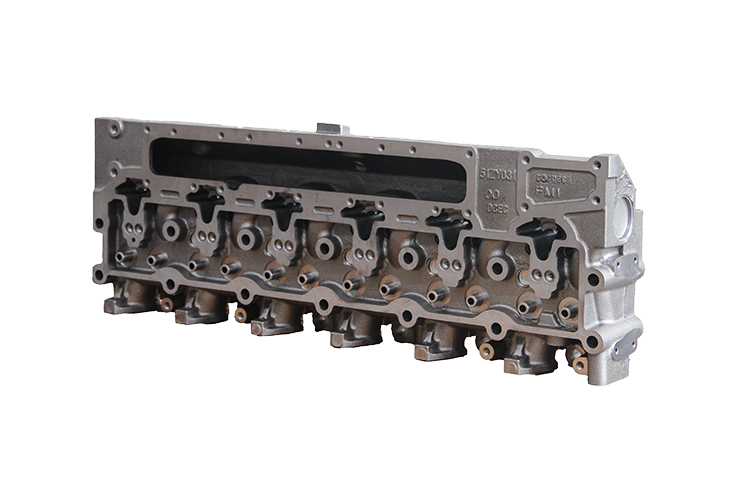

Based on Material:

- Cast Iron: Traditional material, durable, good heat retention, heavier.

- Aluminum Alloy: Lighter weight, better heat dissipation, improves fuel efficiency and performance, more common in modern engines.

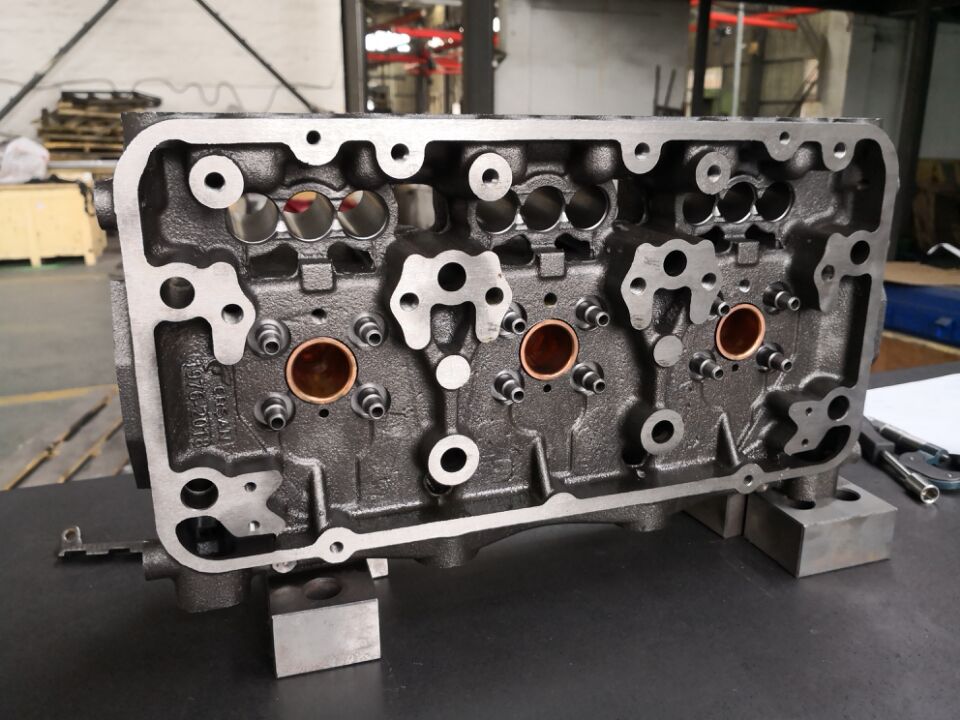

3. What are the Key Components of a Cylinder Head?

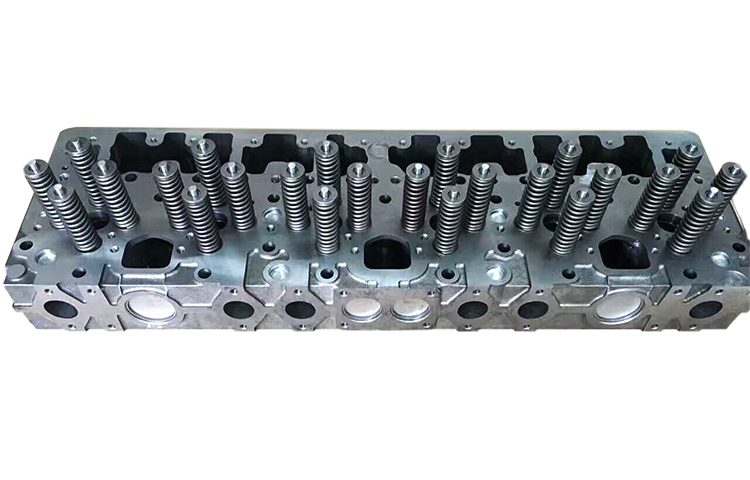

The cylinder head is a complex assembly of parts working in harmony. Here are some of the main players:

- Cylinder Head Casting: The main body of the cylinder head, usually made of cast iron or aluminum, containing ports and passages.

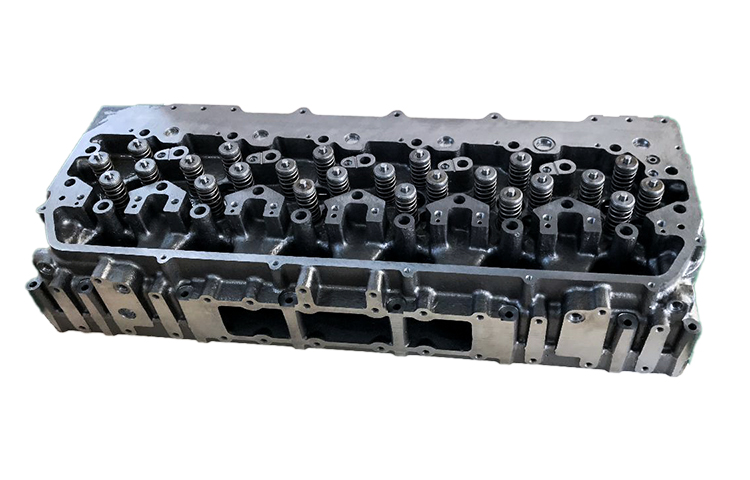

- Valves (Intake and Exhaust): Precisely control the flow of air-fuel mixture into the cylinder and exhaust gases out.

- Valve Seats: Hardened rings inserted into the cylinder head where valves seal against to maintain compression.

- Valve Guides: Bushings that guide the valve stems, ensuring proper valve movement and alignment.

- Valve Springs: Close the valves after they are opened by the camshaft and keep them seated.

- Valve Retainers and Locks: Secure the valve springs to the valves.

- Camshaft(s) (in OHC engines): Rotating shaft with lobes that open and close the valves at precise times.

- Rocker Arms or Followers: Used in OHV and some OHC engines to transmit camshaft motion to the valves.

- Spark Plugs (Gasoline Engines) or Fuel Injectors (Diesel Engines): Initiate combustion or deliver fuel into the cylinder.

- Coolant Passages: Channels within the head for coolant circulation to manage heat.

- Oil Passages: Channels for lubricating valve train components.

4. Why is the Cylinder Head So Important for Engine Performance?

The cylinder head is not just a passive component; it's crucial for achieving optimal engine performance, efficiency, and emissions.

Significance for Engine Performance:

- Combustion Efficiency: A properly designed and functioning cylinder head ensures a tight seal for efficient combustion, maximizing power output from the fuel.

- Volumetric Efficiency (Engine Breathing): The design of intake and exhaust ports in the cylinder head significantly impacts how well the engine "breathes," affecting power and torque.

- Heat Management: Efficient heat dissipation through the cylinder head's coolant passages prevents overheating and engine damage, ensuring reliable operation.

- Valve Control and Timing: The cylinder head houses and supports the valve train, which precisely controls valve timing and lift, critical for engine performance and fuel economy.

- Emissions Control: Efficient combustion and proper exhaust flow, influenced by cylinder head design, are vital for minimizing harmful emissions.

5. How Does a Cylinder Head Actually Work?

The cylinder head's operation is intricately linked to the four strokes of a typical internal combustion engine: Intake, Compression, Combustion (Power), and Exhaust.

[Include a video animation of cylinder head operation - Searching for "cylinder head animation video engine cycle"]

Cylinder Head in Engine Cycle:

- Intake Stroke: The intake valve(s) in the cylinder head open, allowing the air-fuel mixture (or just air in diesel engines) to be drawn into the cylinder as the piston moves down.

- Compression Stroke: Both intake and exhaust valves are closed, sealed by the cylinder head. The piston moves up, compressing the air-fuel mixture. The cylinder head's sealing is critical here to build pressure.

- Combustion (Power) Stroke: The spark plug (gasoline) or fuel injector (diesel) in the cylinder head ignites the compressed mixture. The controlled explosion forces the piston down, generating power. Again, the cylinder head's seal contains this powerful force.

- Exhaust Stroke: The exhaust valve(s) in the cylinder head open. The piston moves up, pushing the burnt exhaust gases out through the exhaust ports in the cylinder head.

6. What are the Common Problems and Damages that Cylinder Heads Experience?

Due to the extreme conditions it operates under, the cylinder head is susceptible to various problems:

- Cracking: Thermal stress from extreme temperature changes can cause cracks in the cylinder head casting, especially in cast iron heads.

- Warpage: Overheating can cause the cylinder head to warp or distort, leading to leaks and poor sealing.

- Gasket Failure (Head Gasket): The head gasket seals the cylinder head to the engine block. Overheating, improper torque, or age can cause it to fail, leading to coolant or oil leaks, and compression loss.

- Valve Problems:

- Burnt Valves: Excessive heat or poor sealing can burn valve faces.

- Valve Seat Recession: Valve seats can wear down over time, affecting valve sealing.

- Valve Guide Wear: Worn valve guides can cause valve misalignment and oil leaks.

- Port Blockage: Carbon buildup in intake or exhaust ports can restrict airflow.

- Thread Damage: Spark plug or bolt threads in the cylinder head can be stripped.

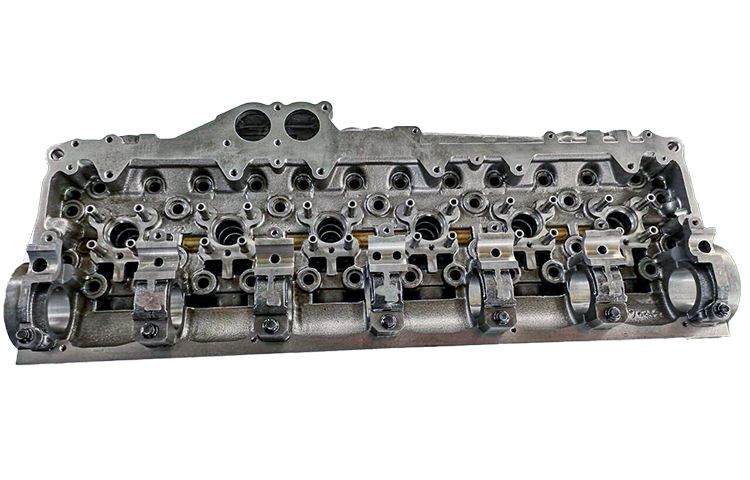

7. How are Cylinder Heads Repaired and Refurbished?

Depending on the type and severity of damage, cylinder heads can often be repaired or refurbished, saving the cost of a complete replacement. Common repair methods include:

- Cylinder Head Machining/Resurfacing: For warped cylinder heads, the mating surface can be machined flat again.

- Valve Job: Involves grinding valve seats and valves to ensure proper sealing. Valve guides and seals can also be replaced.

- Crack Repair: Cast iron cylinder heads can sometimes be welded to repair cracks, followed by machining. Aluminum head crack repair is more complex and may involve specialized welding techniques.

- Thread Repair: Damaged threads can be repaired using thread inserts (like Heli-Coils).

- Cleaning and Decarbonizing: Ports and combustion chambers are cleaned to remove carbon deposits.

- Pressure Testing: Cylinder heads are often pressure tested after repair to check for leaks.

8. What are the Technical Challenges in Cylinder Head Design and Repair?

Both designing and repairing cylinder heads present significant technical challenges:

Design Challenges:

- Complex Geometry: Cylinder heads have intricate shapes with ports, passages, and valve train features, making casting and machining complex.

- Thermal Management: Designing efficient coolant passages and material selection to handle extreme heat is crucial.

- Strength and Durability: The cylinder head must withstand immense combustion pressures and thermal stresses over the engine's lifespan.

- Optimizing Flow Dynamics: Intake and exhaust port design must be optimized for efficient airflow and minimal restriction to maximize engine performance.

- Weight Reduction: Especially in modern engines, there's a drive to reduce cylinder head weight (using aluminum) for better fuel efficiency and handling.

Repair Challenges:

- Precision Machining: Cylinder head repair requires high precision machining equipment and skilled technicians to ensure accurate resurfacing and valve jobs.

- Material Expertise: Welding and repairing cracks, especially in aluminum heads, requires specialized techniques and understanding of material properties.

- Leak Testing: Ensuring a leak-free repair after welding or machining is critical, requiring pressure testing and careful inspection.

- Restoring Original Geometry: Maintaining the original combustion chamber shape and port dimensions during repair is important for preserving engine performance.

Dead Cylinder Head Repair | How To Restore Cylinder Head | Complete Restoration Of a Cylinder Head

In Conclusion:

The cylinder head is a marvel of engineering, a complex component that is vital to the heart of your vehicle – the engine. Understanding its function, types, and common issues can help you appreciate the intricate workings of your car and the importance of proper engine maintenance. While cylinder head repair can be challenging, skilled technicians and advanced techniques can often restore these components to their optimal working condition, ensuring your engine continues to run smoothly and powerfully.