Technical News

Cylinder Block: 8 Questions to Explore the Engine’s Backbone

The cylinder block is the unsung hero of your car's engine. Often hidden from view, this massive component forms the foundation upon which the entire engine is built. It's the strong core that houses the cylinders and crankshaft, enduring immense forces and heat. But what exactly is a cylinder block, and why is it so crucial? Let's delve into 8 key questions to understand the essential role of the cylinder block.

1. What is a Cylinder Block and What Does it Do?

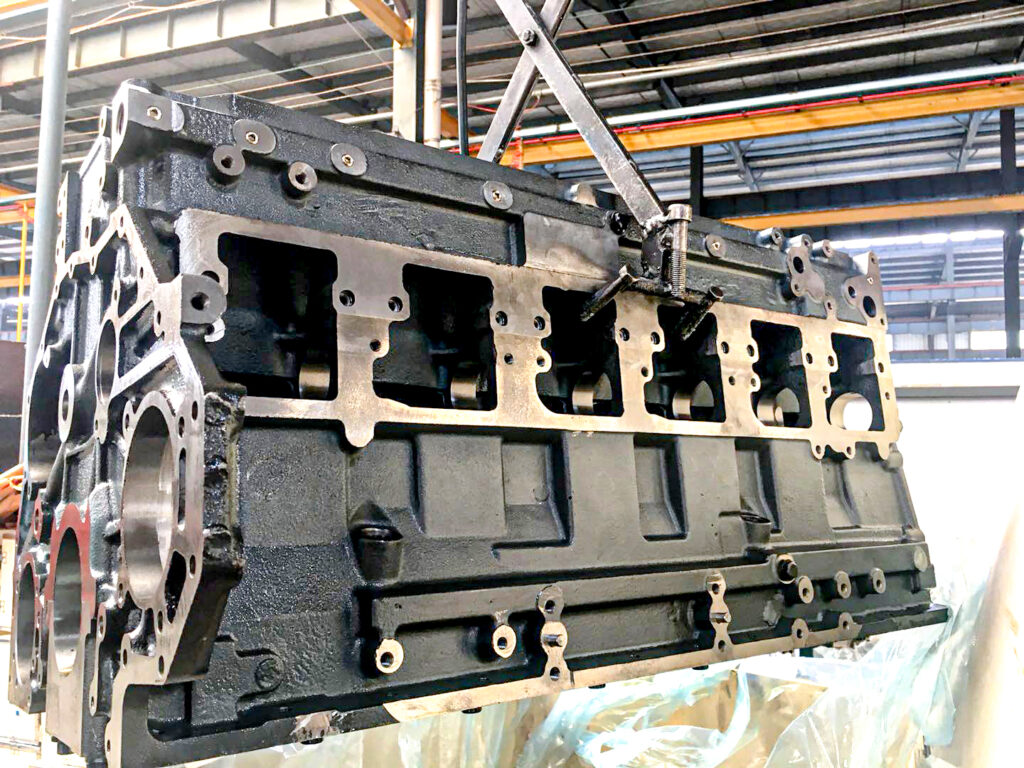

Think of the cylinder block as the main body or skeleton of your car's engine. It's the largest and heaviest part, typically a single casting, and it's where the engine's power-producing cylinders are located. The cylinder block provides the structural framework and critical passageways for the engine to operate.

Key Functions of a Cylinder Block:

- Houses Cylinders: The most obvious function - it contains the cylinders, which are the chambers where pistons move and combustion occurs. Cylinder blocks are designed for engines with different numbers of cylinders (e.g., 4-cylinder, 6-cylinder, 8-cylinder).

- Supports the Crankshaft: The cylinder block provides main bearing journals that precisely hold the crankshaft, allowing it to rotate smoothly and transfer power.

- Contains Coolant Passages: Intricate channels cast within the block form part of the engine's cooling system, allowing coolant to circulate and remove heat from critical areas.

- Contains Oil Passages: Oil galleries are also cast into the block, providing pathways for lubricating oil to reach bearings, pistons, and other moving parts.

- Provides Mounting Points: The cylinder block has surfaces and bolt holes for mounting the cylinder head, oil pan, engine mounts, and other engine accessories.

- Forms the Lower Part of the Crankcase: The lower portion of the cylinder block, often called the crankcase, encloses the crankshaft and connecting rods.

2. What are the Different Types of Cylinder Blocks?

Cylinder blocks come in various configurations, primarily defined by cylinder arrangement and manufacturing materials:

Based on Cylinder Arrangement:

- Inline (Straight) Engine: Cylinders are arranged in a single row. Simple design, compact length, but can be tall for larger engines. (e.g., Inline-4, Inline-6)

- V-Engine: Cylinders are arranged in two rows, forming a "V" shape. Shorter and lower profile than inline engines, good balance. (e.g., V6, V8)

- Flat (Boxer) Engine: Cylinders are horizontally opposed, lying flat on either side of the crankshaft. Very low profile, excellent balance, often used in Subaru and Porsche engines.

- W-Engine: A more complex arrangement with cylinders in a "W" configuration, combining features of V and inline engines. (e.g., W12, W16 - less common)

Based on Material:

- Cast Iron: Traditional material, strong, durable, good vibration damping, heavier. Often used in older engines and some heavy-duty applications.

- Aluminum Alloy: Lighter weight, better heat dissipation, improves fuel efficiency and performance, becoming increasingly common in modern engines to reduce vehicle weight. May require iron cylinder liners for wear resistance.

3. What are the Key Components Integrated into a Cylinder Block?

While the cylinder block itself is a large casting, it integrates with many other essential engine components:

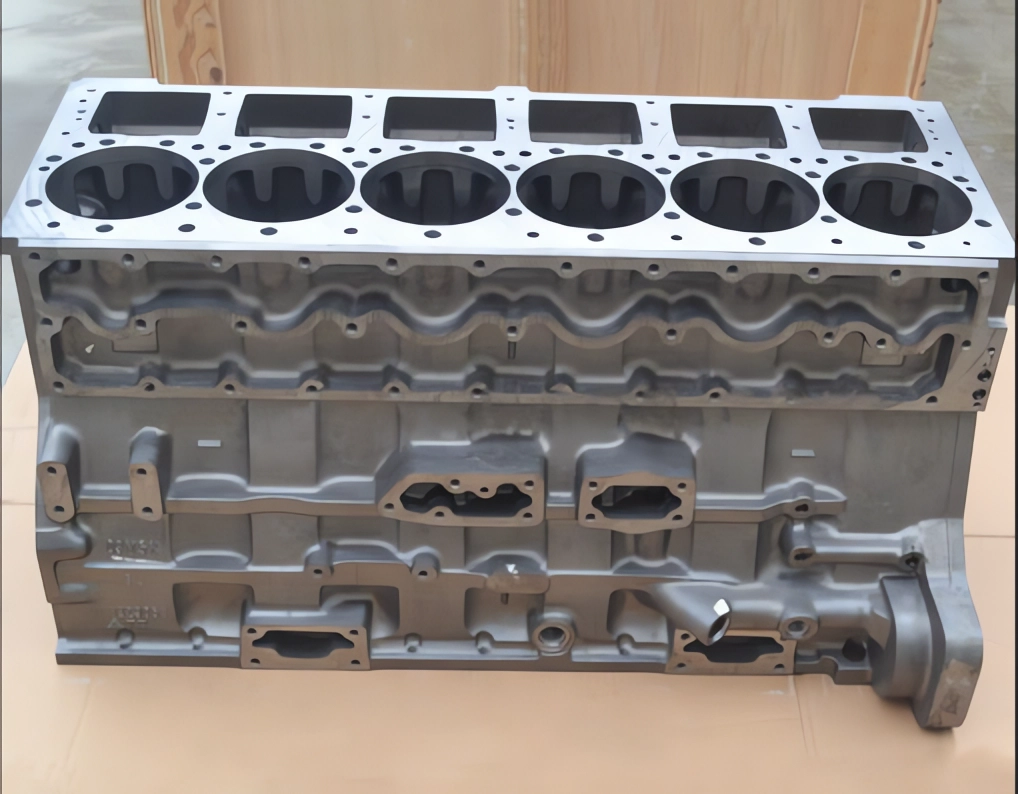

- Cylinders: The bores machined into the block where pistons reciprocate. Can be integral to the block (in cast iron blocks) or have separate liners (often in aluminum blocks).

- Main Bearing Journals: Precisely machined surfaces that hold the crankshaft main bearings, supporting the crankshaft's rotation.

- Coolant Jackets/Passages: Intricate internal channels for coolant circulation throughout the block.

- Oil Galleries/Passages: Internal channels for lubricating oil distribution.

- Cylinder Liners (Sleeves): Removable sleeves inserted into the cylinder bores, often made of cast iron, providing a wear-resistant surface for piston rings. Common in aluminum blocks.

- Water Jackets: The spaces surrounding the cylinders through which coolant flows.

- Mounting Flanges and Bolt Holes: Surfaces and holes for attaching the cylinder head, oil pan, engine mounts, and other components.

4. Why is the Cylinder Block Considered the Engine's Foundation?

The cylinder block is truly the foundation of the engine, providing structural integrity and enabling all other engine systems to function correctly.

Significance as Engine Foundation:

- Structural Backbone: It provides the rigid framework that holds all the engine's components in precise alignment. It must withstand immense combustion forces and vibrations.

- Alignment and Precision: The cylinder block's precise machining of cylinder bores and main bearing journals ensures proper piston and crankshaft movement, crucial for engine balance and longevity.

- Integration Hub: It acts as a central hub, integrating the combustion chambers, cooling system, lubrication system, and mounting points for other engine systems.

- Durability and Longevity: The robust construction of the cylinder block dictates the overall durability and lifespan of the engine. A strong block is essential for reliable operation under demanding conditions.

5. How is a Cylinder Block Manufactured?

Cylinder block manufacturing is a complex process, typically involving casting and precision machining:

[Include a video of cylinder block manufacturing process - Searching for "cylinder block manufacturing process video"]

Typical Manufacturing Steps:

- Pattern Making: Creating a precise pattern (often from wood or resin) that represents the shape of the cylinder block casting.

- Mold Making: Using the pattern to create a mold from sand or other casting materials.The mold includes the negative space for the cylinder block shape, including internal passages.

- Casting: Molten metal (cast iron or aluminum alloy) is poured into the mold.

- Cooling and Solidification: The casting is allowed to cool and solidify within the mold.

- Mold Removal (Shakeout): The sand mold is broken away to reveal the raw casting.

- Cleaning and Deburring: The casting is cleaned of sand and excess material (flash).

- Heat Treatment (Stress Relieving): The casting may be heat-treated to relieve internal stresses and improve material properties.

- Rough Machining: Initial machining operations to establish basic surfaces and dimensions.

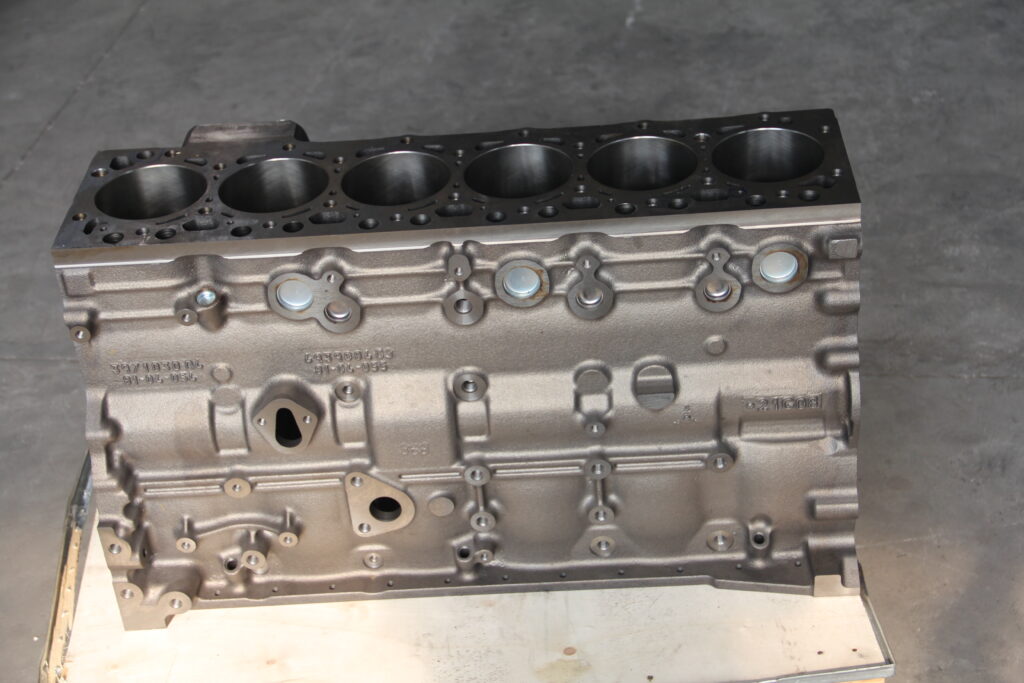

- Precision Machining: Highly accurate machining of cylinder bores, main bearing journals, and other critical surfaces to final specifications.This includes honing cylinder bores for optimal piston ring sealing.

- Cleaning and Inspection: Thorough cleaning and inspection for dimensional accuracy, surface finish, and casting defects.

6. What are the Common Problems and Damages that Cylinder Blocks Experience?

Despite their robust nature, cylinder blocks can suffer damage, often due to extreme conditions or neglect:

- Cracking: Extreme stress from overheating, freezing coolant, or severe mechanical shock can cause cracks in the block casting. Cracks can be very serious, leading to coolant or oil leaks, and loss of structural integrity.

- Warpage/Distortion: Overheating can cause the block to warp, particularly the cylinder head mating surface or main bearing journals, leading to sealing problems and crankshaft misalignment.

- Cylinder Bore Wear: Piston ring friction over time can wear down cylinder bores, leading to increased oil consumption and reduced compression.

- Bearing Journal Damage: Bearing failure or lack of lubrication can damage main bearing journals, requiring extensive machining or block replacement.

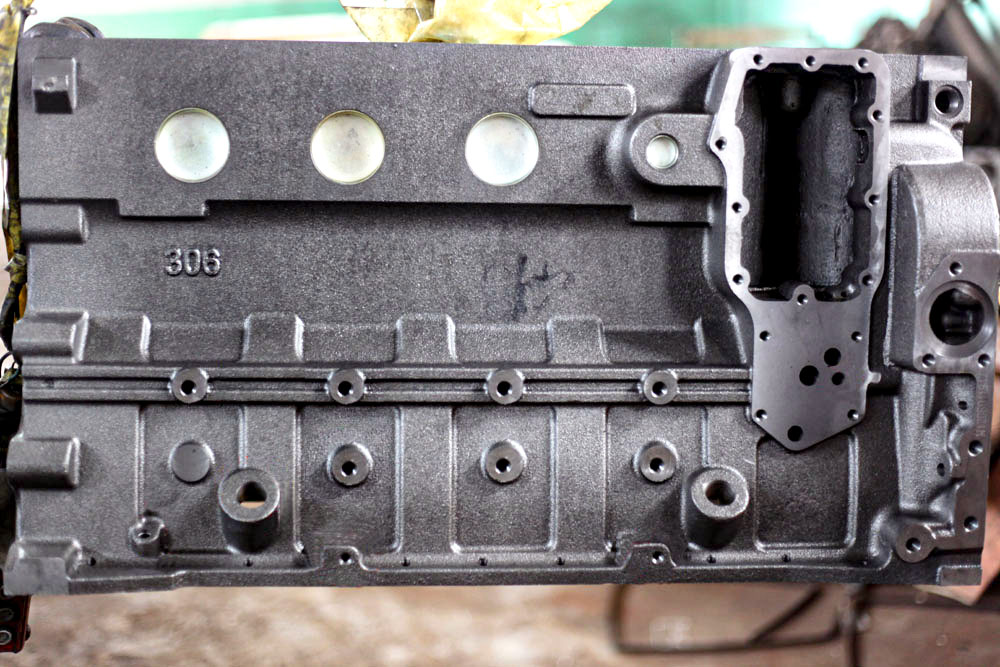

- Freeze Plug/Core Plug Leaks: Freeze plugs (also called core plugs or Welch plugs) seal coolant passages in the block. Corrosion or freezing can cause them to leak.

- Thread Damage: Bolt holes for engine mounts or accessories can have stripped threads.

7. How are Cylinder Blocks Repaired and Refurbished?

Repairing a cylinder block is often complex and costly, but sometimes feasible depending on the damage:

- Crack Repair (Cast Iron Blocks): Cast iron blocks can sometimes be welded to repair cracks, often using specialized welding techniques like furnace welding or metal stitching.Success depends on crack location and severity.

- Cylinder Boring and Honing: Worn cylinder bores can be enlarged by boring and then honed to the correct size to accommodate oversized pistons.

- Cylinder Sleeving/Lining: For severely worn or damaged cylinders, new cylinder liners can be installed. This is common for aluminum blocks and for repairing severely damaged cast iron blocks.

- Main Bearing Journal Line Boring/Honing: Damaged main bearing journals can sometimes be machined back to roundness and alignment (line boring), or honed if slightly worn.

- Freeze Plug Replacement: Leaking or corroded freeze plugs are relatively easy to replace.

- Thread Repair: Damaged threads can be repaired using thread inserts (like Heli-Coils).

- Block Decking/Resurfacing: The cylinder head mating surface can be resurfaced to correct minor warpage.

8. What are the Technical Challenges in Cylinder Block Design and Repair?

Cylinder blocks present significant engineering challenges in both design and repair:

Design Challenges:

- Structural Integrity: Designing a block that can withstand immense combustion forces and vibrations while remaining relatively lightweight.

- Casting Complexity: Creating intricate internal passages for coolant and oil flow within a single casting.

- Thermal Management: Efficiently dissipating heat from the cylinders to prevent overheating and ensure even temperature distribution.

- Manufacturing Precision: Achieving extremely tight tolerances in cylinder bores and bearing journals during mass production.29

- Material Selection: Choosing materials that balance strength, weight, cost, and machinability.

Repair Challenges:

- Complexity of Damage Assessment: Diagnosing the extent of internal block damage (cracks, warpage) can be difficult and require specialized inspection techniques.

- Precision Machining: Cylinder block repair demands high precision machining equipment and skilled machinists to restore critical dimensions and alignments.

- Heat Management During Repair: Welding cast iron blocks requires careful heat control to prevent further cracking or distortion.

- Ensuring Long-Term Durability: Repaired blocks must be able to withstand continued heavy-duty operation and provide reliable service life.

Dead Cylinder Head Repair | How To Restore Cylinder Head | Complete Restoration Of a Cylinder HeadWhich One is The Best for the Engine Blocks?

In Conclusion:

The cylinder block is a masterpiece of engineering, the robust heart of the engine. Its seemingly simple form hides a complex network of passages and precisely machined surfaces that are essential for engine operation. Understanding the cylinder block's function, types, and potential problems highlights its crucial role in vehicle performance and longevity. While cylinder block repair can be a significant undertaking, skilled machinists can often restore these foundational components, extending engine life and keeping vehicles running reliably.